Driving Energy Excellence with Customer Care and Quality

Emerald Oil & Gas delivers quality, reliability, and innovation, with customer care at the heart of everything we do.

Our Clients

About Us

Driving Excellence In Oil & Gas Solutions

We are a team of professionals from every field related to Oil & Gas Upstream Services, Engineering Procurement & Construction (EPC), Oil & Gas Chemicals (for Drilling, Cementing & Stimulation), Robotic Applications, Industrial Automation, Principal Trading & Modern Technologies (Business Engineering, Business Intelligence & Value Engineering).

Our Services

Comprehensive Solutions for Every Industry

Front End Engineering Design, FEED

Emerald’s Estimation team has a proven track record of studying, crafting, and implement….

Engineering, Procurement & Construction (EPC)

Emerald has the capability to provide Engineering and Design Services across multiple sectors…

Testing and Commissioning

Testing and Commissioning of the installed equipment is crucial to the success completion of the project.

Project Management

Clients have to confront complex issues in every area of construction right from site preparation to technology…..

Turnkey Projects

Emerald has the capability to designate project managers and engineers who are experts in executi…

Modifications & Revamping

Emerald has the capability to designate project managers and engineers who are experts in conducting site surveys…

Our Projects

Showcasing Excellence

in Every Project

Upgradation of Plant Control System at DR-1

The “Upgradation of Plant Control System at DR-1” project, located onshore in Qatar, focused on modernizing the plant’s control infrastructure. The scope of work included the supply, installation, splicing, and testing of fiber optic cables; dismantling existing panels and installing new ones; re-routing and replacing existing panels; and installing checker plates with frames. Additionally, the project involved commissioning field instruments and the control system. Delivered for Honeywell/Qatar Steel, the project was successfully completed between August and September 2013, showcasing expertise in advanced control system upgrades.

ASAB 3 (A3)/ LSP & Lightning Protection System

The “ASAB 3 (A3)/ LSP & Lightning Protection System” project, located in ASAB, onshore in the United Arab Emirates, involved basic engineering, supply, installation, pre-commissioning, commissioning assistance, and startup support. The scope of work included armored cables, switches, sockets, cable trays, and GI conduits with fixing accessories. Delivered for ADNOC Gas Processing, the project focused on enhancing safety and electrical infrastructure. Successfully executed between May 2011 and September 2012, it underscored expertise in implementing robust lightning protection and support systems.

Solar Street Lighting Project – Habshan, UAE

The “EPC for Provision of Solar Street Lighting System from Habshan-5 Junction to Habshan Plant Junction on Tarif-Habshan Road” project, located in Habshan, onshore in the United Arab Emirates, focused on delivering a sustainable solar street lighting solution. The scope included design, detailed engineering, manufacturing, integration, shop testing, packing and forwarding, transportation, supply, installation, testing, and commissioning of the system. Executed for ADNOC Gas Processing, the project demonstrated a commitment to renewable energy and infrastructure development. It was successfully realized between January 2014 and January 2017.

Upgrade of 3.3KV & 11KV Switchboards at Substations

The “Upgrade of 3.3KV & 11KV Switchboards at Substations” project, located in Habshan, onshore in the United Arab Emirates, involved the Engineering, Procurement, and Construction (EPC) of upgraded 3.3KV switchboards at Substations 2, 3, and 6, as well as 11KV switchboards at Substation 5. Delivered for ADNOC Gas Processing, the project aimed to enhance the performance and reliability of the power distribution infrastructure. Successfully executed between 2016 and 2018, it reflects expertise in modernizing critical electrical systems.

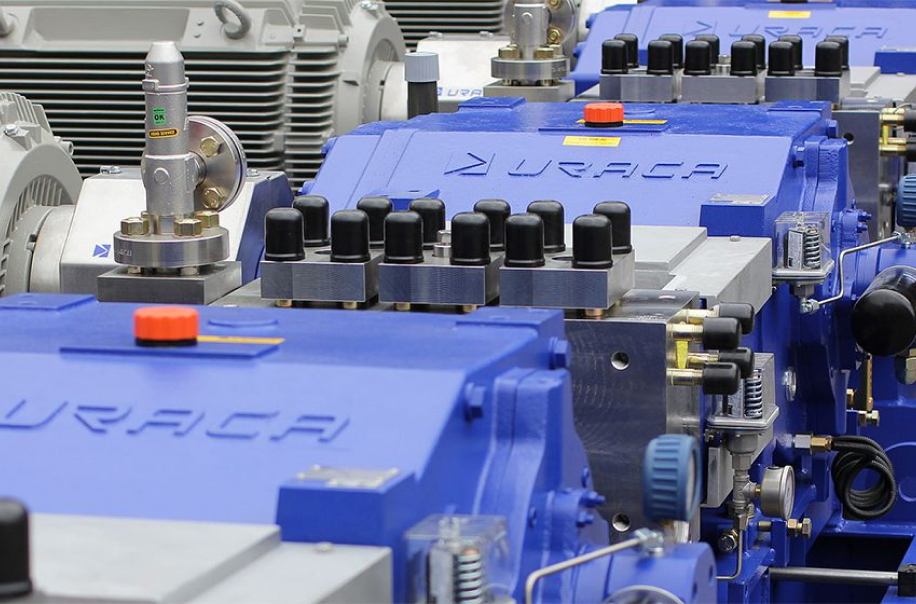

UPGRADATION OF EXISTING URACA PUMPS

The “Upgradation of Existing URACA Pumps” project, located in Ruwais, onshore in the United Arab Emirates, focused on the supply, installation, testing, and commissioning of cable ladder racks and power cables for URACA pump motors. Executed for ADNOC Fertilizers, the project aimed to enhance the operational efficiency and reliability of the pump systems. Successfully completed between August 2013 and February 2014, it demonstrated proficiency in upgrading critical infrastructure within the industrial sector.

AMC for E&I works in DNO Platform

The “AMC for E&I Works in DNO Platform” project, located onshore in Ras Al Khaimah (RAK), United Arab Emirates, involved an Annual Maintenance Contract (AMC) for electrical and instrumentation works on the DNO Platform. Delivered for DNO, this project emphasized the maintenance and reliability of critical systems, ensuring seamless operations. The project was successfully realized in 2016, highlighting a commitment to excellence in the energy sector.

Upgradation of SCADA system in dolphin plant

The “Upgradation of SCADA System in Dolphin Plant” project, located offshore in the United Arab Emirates, focused on the design, engineering, supply, and installation of 3.3 KV and 11 KV transformers. Executed for Bunduq, the project aimed to enhance the Supervisory Control and Data Acquisition (SCADA) system, ensuring improved operational efficiency and reliability in the Dolphin Plant. The project was successfully completed in 2017, showcasing expertise in modernizing offshore energy infrastructure.

AMC for Transformers, Fire & Gas System and CCTV system

The “AMC for Transformers, Fire & Gas System, and CCTV System” project was undertaken in Shah Field, an onshore location in the United Arab Emirates. This project involved an Annual Maintenance Contract (AMC) covering 311 transformers, fire and gas systems, and CCTV systems in the Shah Gas facilities. Delivered for ADNOC Sour Gas, the project ensured the reliability and optimal performance of critical infrastructure over a seven-year period, from 2016 to 2023.

EPC For Tie In Works at South East - Package A

The “EPC for Tie-In Works at South East – Package A” project, located in the United Arab Emirates, involved onshore operations focused on the installation, testing, and commissioning of electrical works associated with gas lift wells and a multi-selector manifold. This project was undertaken for ADNOC Onshore, one of the region’s prominent oil and gas entities, demonstrating a commitment to enhancing infrastructure in the sector.

The project spanned from April 2015 to April 2018, showcasing expertise in providing comprehensive EPC (Engineering, Procurement, and Construction) services for complex onshore installations.

ELV back bone network system for ADNOC Ruwais Housing Complex – Phase IV.

The “ELV Backbone Network System for ADNOC Ruwais Housing Complex – Phase IV” project was located in Ruwais, onshore in the United Arab Emirates. This project involved the Engineering, Procurement, and Construction (EPC) of a fiber optic cabling system to establish an ELV (Extra Low Voltage) backbone network system. Delivered for ADNOC, the project demonstrated expertise in implementing advanced networking solutions to support critical infrastructure. The project was successfully completed between 2016 and 2017.

HV / LV Electrical Systems Upgrade

The “HV / LV Electrical Systems Upgrade” project, located at the Umm Shaif Super Complex offshore in the United Arab Emirates, involved the detailed engineering, design, procurement, and construction of HV (High Voltage) switchgears, LV (Low Voltage) switchgears, and transformers. This project was undertaken for ADNOC Offshore, showcasing advanced capabilities in modernizing critical electrical systems in offshore environments. The project was successfully realized from 2017 to 2013, reflecting expertise in delivering high-quality, backward-compatible solutions for complex energy infrastructures.

Call Off Contract

The “Call Off Contract” project, located in Umm Shaif, Offshore in the United Arab Emirates, focused on electrical and instrumentation works across UZ (Upper Zakum) and LZ (Lower Zakum) fields. Undertaken for ADNOC Offshore, the project showcased adaptability and expertise in delivering specialized services in challenging offshore environments. Spanning from 2016 to 2022, this long-term project highlights a commitment to operational excellence and sustained collaboration within the oil and gas sector.

Renovation Of DAS Island Multipurpose Sports Hall

The “Renovation of Das Island Multipurpose Sports Hall” project, situated on Das Island in the United Arab Emirates, focused on offshore operations to revitalize the facility. The scope of work included comprehensive EPC (Engineering, Procurement, and Construction) services for electromechanical systems, instrumentation, telecommunication, and HVAC systems. Executed for GCC/ADNOC LNG, this project demonstrated expertise in delivering high-quality renovation services tailored to offshore environments. The project was successfully realized between September 2013 and June 2014, reflecting a commitment to excellence in infrastructure development.

Interconnection of ADWEC CRS to DEL at Taweelah

The “Interconnection of ADWEC CRS to DEL at Taweelah” project, located in the United Arab Emirates, involved onshore operations focusing on the installation, testing, and commissioning of a gas metering skid along with its associated instrumentation and electrical systems. Undertaken for ADNOC Gas Processing, this project highlights expertise in delivering integrated solutions for critical energy infrastructure.Successfully executed between March 2015 and September 2016, the project showcases a commitment to precision and excellence in the oil and gas sector.

EPC For Tie In Works at South East - Package C

The “EPC for Tie-In Works at South East – Package C” project, based in the United Arab Emirates, focused on onshore operations involving the installation, testing, and commissioning of electrical works related to gas lift wells and a multi-selector manifold. Executed for ADNOC Onshore, a key player in the region’s oil and gas industry, the project reflects a strong capability in delivering complex EPC (Engineering, Procurement, and Construction) services.

Spanning from July 2018 to July 2023, the project underscores a commitment to excellence and innovation in the energy sector.

Our Areas of Expertise

Innovative Solutions for

Industrial Challenges

Industrial Automation

Emerald has been providing innovative solutions in design and engineering, product development, special-purpose machines (SPMs), machine tool automation, welding automation, and control systems industries for many years.

Engineering Procurement & Construction

Since its infrastructure has a major impact on cities, regions, and their citizens, Emerald aims for quality, technically sound, economically viable, environmentally friendly, and socially beneficial performance.

Chemical Engineering

In the oil and gas industry, perfect chemistry is everything. Whether it’s optimizing challenges, safeguarding people and the environment, or fostering a highly successful client-supplier relationship, Emerald – Oilfield Chemical Supplier has the chemistry you’re looking for.

Trading

Trading is one of our fastest-growing entities across the GCC region, with offices located in all major cities. With over 40 years of industry experience and in partnership with Emerald, we have expanded our presence in several major projects across the region.

Robotic Application

Robotics has found its way into many different areas in manufacturing. Robots perform tasks like welding, assembly, shipping, handling raw materials, and product packing. Manufacturers are leveraging robotic automation for a wider number of applications.

Project Staffing

We provide full cycle project staffing services. If you need a project team to be onboarded or for individual staff requisite, our recruitment team is fully capable of handling your workforce needs.

Let's Build the Future Together

Discover innovative solutions tailored to your industry. Let’s connect to discuss your specific needs, explore our cutting-edge technologies, and unlock the potential for growth and efficiency